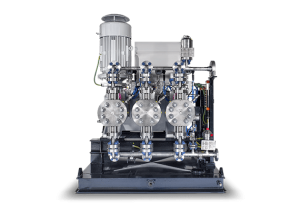

Metering pumps

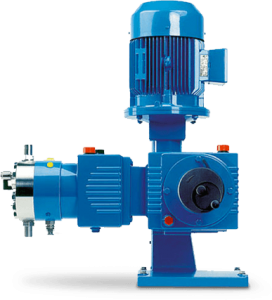

Diaphragm metering pump

It features an exact metering rate and enormous durability in extreme operating conditions. Low life cycle costs and high energy efficiency complete the profile of a true all-around talent.

No matter if offshore in rough seas or in production in pharmaceutical cleanrooms – the diaphragm metering pump has established itself worldwide in a range of different industries as a reliable and economical metering pump.

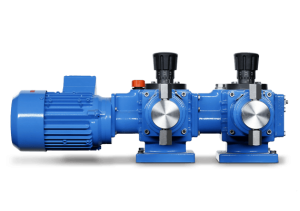

Packed plunger metering pump

The cost-efficient alternative for simple metering tasks.

It does not always have to be expensive: In many cases, the use of complex diaphragm metering pumps is not cost-effective when pumping simple fluids. Therefore, we provide the packed plunger metering pump as a cost-efficient alternative.

Therefore, for metering non-critical fluids, such as water or resin, it is advantageous to rely on a simple and robust pump with low acquisition and operating costs.

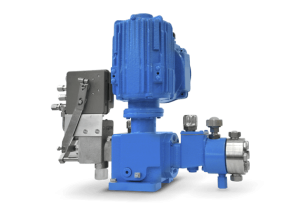

Laboratory pump

Laboratory pumps for extremely small flow rates.

In laboratories, test centers and other testing environments, small amounts of liquid media often have to be metered. Great value is placed on operational reliability and a broad spectrum of use in these environments. The metered flows have to be reproducible and controllable with high precision. The fluid has to be protected from any impurities.

So that it can be used in a wide variety of application areas and fulfill the specific requirements of our customers, it is available in two different designs: as a diaphragm pump or packed plunger metering pump.

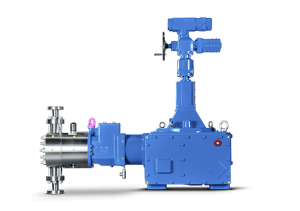

Process pump

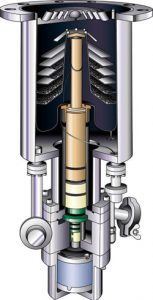

Diaphragm process pump

The AEG’s diaphragm process pump is an advanced pump for high-pressure process technology. It features a variable modular design and provides the right solution for a vast assortment of industrial applications.

The DPS diaphragm protection system ensures maximum process reliability. The diaphragm process pump achieves flow rates of up to 19 m3/h per pump head and discharge pressures of up to 1200 bar.

Process pump for high-pressure processes

Compact, rugged, reliable.

Whether in the oil and gas industry, the chemical industry, the food industry or the energy sector, the AEG triplex diaphragm process pump has been used everywhere in high-pressure applications.

The pump features tried-and-tested, patented AEG diaphragm technology, absolutely secure and reliable operation and the world’s most compact design for a process pump. It also has the advantages of a long service life, minimal life cycle costs and high energy efficiency.

Centrifugal pumps

Cryogenic pump

The solution for transferring liquefied petroleum gas.

A special cryogenic submersible motor eliminates the danger of leaks and simplifies pump mounting. The bearings have a long service life by a minimal bearing load design. The pumps are available in different models such as those installed in storage tanks, out of which they can be taken when installing in a condensate tank or for fixed installation in tankers.

Moreover, we offer tests in our pump test facility with LNG at -162 °C.

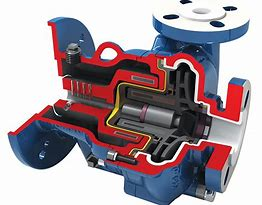

Magnetic drive pumps

Technology: Single-stage, plastic-lined, sealless and mechanical seal standard chemical pumps (centrifugal pumps) .

The important innovations include magnetic coupling pumps , slide bushings optimized for dry running and for solids up to 30% as well as pump monitoring, which continuously monitors the measuring and operating data of the magnetic drive pumps. AEG pumps provide the perfect alternative for pumps made of expensive and exotic metals for media that contain solids, crystallize or that are toxic, hot or supercritical in some other way.